Is the forum going to live on, even though it's not active any more?

When does all the hosting/domain registration, etc. run out?

When does all the hosting/domain registration, etc. run out?

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

Quote from: Incursus on August 22, 2016, 01:56:39 PM

Maybe.. :chiny: How much would you be looking for?

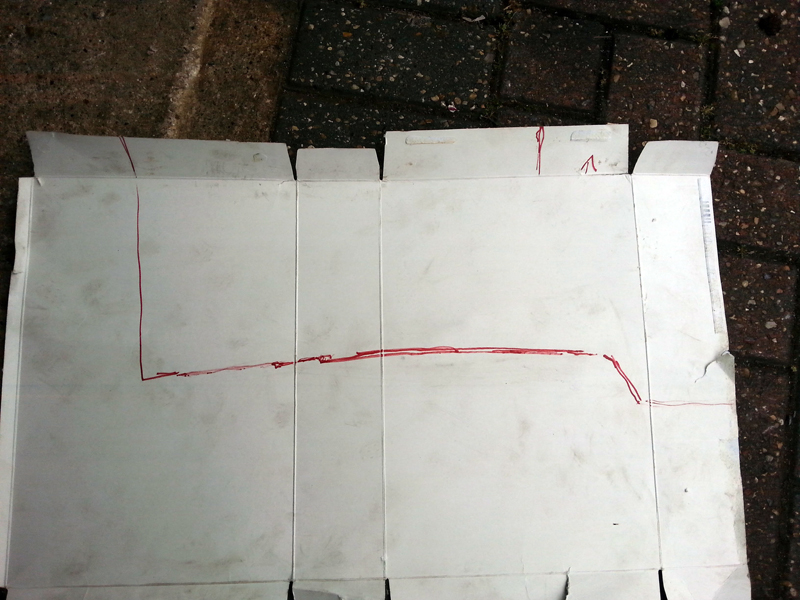

Any pics?

Quote from: FUBAR on June 07, 2016, 06:53:11 PMI like this, its a good discussion.